How To Fix Your Gas Turbine

One of the most important aspects of your business is maintaining your product. Gas turbines are expensive pieces of machinery and, as a result, require regular care and maintenance in order to prevent any damage or problems. Some companies make it part of their daily routine, while others operate without any regular upkeep. This article provides advice on how you can create a schedule for necessary repairs so that you can keep your turbines running smoothly!

What is a Gas Turbine?

A gas turbine is a type of engine that uses an air or gas mixture to create power. The turbine blades spin around a central shaft, which converts the energy from the air or gas into kinetic energy. Gas turbines are used in aircraft, ships, and some stationary applications.

If your gas turbine is not running smoothly, there are a few things you can do to get it running like new again. Here are some tips to help diagnose and fix common problems with your turbine:

1) Check the oil level – Make sure the oil level is at least 3/4 full in the oil pan. If the oil level is too low, it will cause the turbine to work harder than necessary and could even cause damage.

2) Check for pre-ignition – Pre-ignition is when the engine starts to ignite before you have put enough fuel into it. This can be caused by dirty air filters, incorrect air-fuel ratios, or an incorrectly timed spark plug.

To check for pre-ignition, turn off the engine and use an ohmmeter to measure resistance between two points on the wire coil (near the spark plugs).

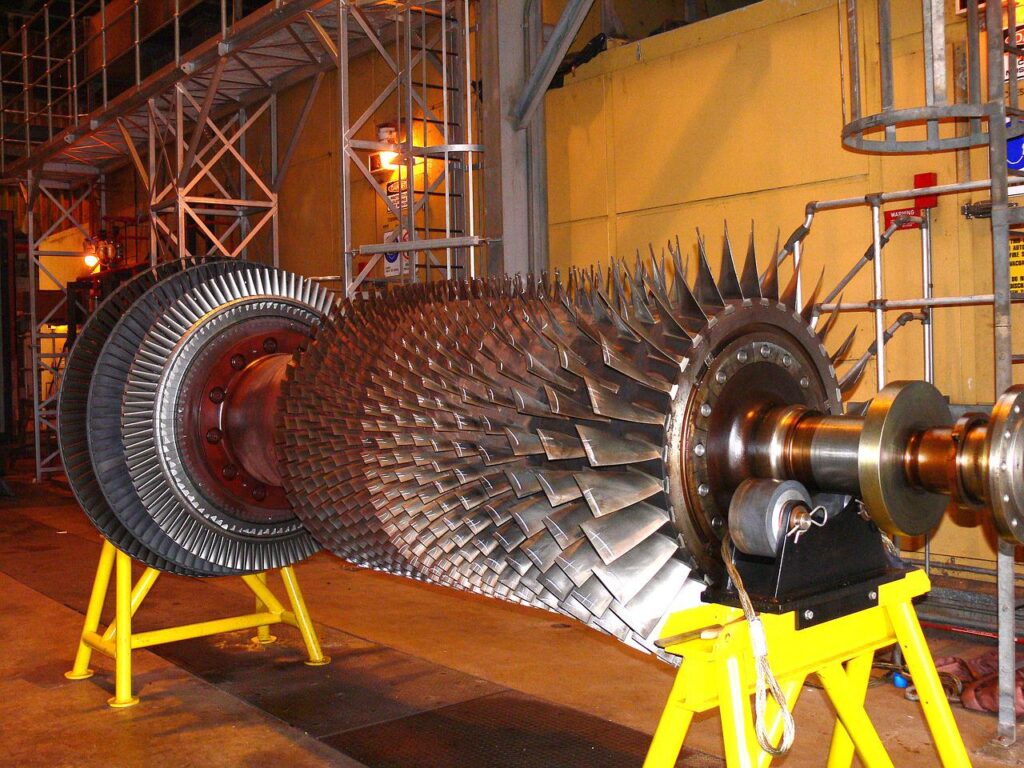

Main Components of a Gas Turbine

A gas turbine is a type of internal combustion engine that uses gas as the working fluid. The engine is used to produce power for aircraft, ships, and other machinery. Gas turbines are made up of several main components. These include the compressor, the combustion chamber, the turbine, and the exhaust system.

The compressor is located at the front of the engine and works to increase the size of the gas mixture that enters the combustion chamber. This mixture is then combusted and used to create energy. The turbine is located at the back of the engine and works to generate mechanical power. The exhaust system helps to expel all of the waste products from the engine.

How to Select the Right Company for Service

When it comes to your gas turbine, you want to make sure you select the right company to service and maintain it. Here are a few tips to help you choose the right gas turbine repair company for your needs.

First, make sure you have a good understanding of the types of gas turbines available. There are three main types: combined cycle, direct drive, and turbomachinery. Each has its own unique features and needs that must be considered when selecting a gas turbine repair company to service and maintain your turbine.

Next, determine what type of service you need. Your turbine may need regular maintenance and repairs, or only specific types of services like overhauls or replacements. Once you have determined what services your turbine needs, look for companies that offer those services.

Finally, consider the company’s reputation. Check with local turbine dealers and other customers who have used the company before to get opinions about how they liked working with them. Talk to friends or family members who work in related industries to get their opinion as well. It is important to choose a reputable company that will take care of your equipment while providing quality service.

Tips for Finding the Right Company in Your Area

If you’re thinking of purchasing a gas turbine, make sure to do your research and choose the right company in your area. Here are a few tips to help you find the right company:

-Ask friends and family members if they know any companies that sell gas turbines.

-Check online reviews to see if anyone has had good or bad experiences with a specific company.

-Talk to other engineers or professionals in the industry to get their opinion on which company is best for you.

Common Problems in Gas Turbines

Gas turbines are machines that convert energy from a gas into rotational motion to create power. They play an important role in powering turbines used in power generation, as well as aircraft and ships. Gas turbines are often reliable and efficient, but they can also suffer from common problems. In this article, we will discuss some of the most common issues with gas turbines and how to fix them.

If your turbine is not producing the expected power level, there are several things you can check to determine the cause. First, make sure the air filters are clean and properly installed. Check for blockages in the airflow path or around the impeller. If these are not the cause of the problem, then check for misfiring valves or switches. Finally, if all of these tests come back to normal, it may be time to replace components such as the engine or gearbox.

If your turbine is producing low power levels or is not running at all, it may be due to a defective engine or gearbox. To determine which part is causing the issue, you will need to do a thorough inspection of both parts.

Common Reasons for Repair

One of the most common reasons for repair on gas turbines is a failed turbine blade. A failed turbine blade can cause decreased power and possible engine failure. In order to prevent this from happening, it is important to keep your turbine blades in good condition. Here are some tips for maintaining your turbine blades:

- Keep your blades clean. Dirty blades will limit the amount of air that can flow through them, which will decrease the power and increase emissions. Clean them with a brush or a cloth dampened with soap and water.

- Seal any cracks or tears in the blade with a sealant. This will help to prevent debris from entering the engine and causing damage.

- Check the blade for wear every six months or 1,000 hours of use, whichever comes first. If it shows excessive wear, replace it immediately.

- Inspect the blade for signs of corrosion, such as green spots on the metal or an increase in weight. Corrosion can lead to blade failure and increased emissions.

Conclusion

If you are experiencing problems with your gas turbine, it is important to get it fixed as soon as possible. By doing so, you can avoid any further damage and keep your machine running smoothly. Here are a few tips on how to fix your gas turbine:

- Make sure the engine is properly fueled and in good working order.

- Inspect all of the seals and make sure they are tight and intact.

- Check for any clogs or debris that may be blocking the engine’s air intake or exhaust valves.

- Clean all of the parts of the engine that come into contact with air.

Pranab Bhandari is an Editor of the Financial Blog “Financebuzz”. Apart from writing informative financial articles for his blog, he is a regular contributor to many national and international publications namely Tweak Your Biz, Growth Rocks ETC.